GangSaw

The cutting system "Zenesis gangsaw" is a new but consolidated technology developed to cut granite blocks

The cutting system “ZENESIS Gang Saw(ZGS) ” is a new but consolidated technology developed to cut granite blocks for which use;

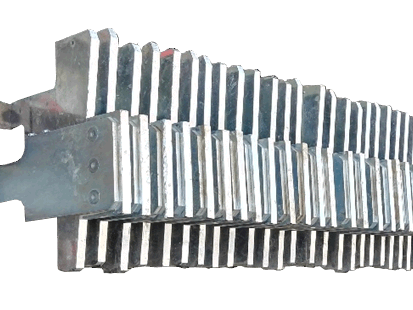

- Hardened steel blades with the special diamond segments

- Pendular movement of the blade itself to give impact on the material to be cut.

This technology, protected by the international patents, has been developed by EHWA Diamond Industrial Co. Ltd. with its headquarter in Korea(south).

The main feature of ZGS can be found in the use of a hardened steel blade with the special diamond segments which are able to cut granite with only water instead of the traditional mixture of water-steel grit-lime. It is possible also to cut marble and other kinds of stone. The diamond segments excellently bear the forward/backward movements and the multiple impacts on the granite and it is possible to reach down feed rate from 100mm/h up to 150 mm/h with higher speed of 200 mm/h in case of particular soft materials.

The advantages of the Zenesis gang saw system

- Width of cut generated by the diamond segment: 5 mm instead of 9 mm of the traditional system

ADDITIONAL PRODUCTION OF THE ZENESIS GANG SAW

Thickness of the slab :21

38 m2/m3

33 m2/m3

35 m2/m3

Thickness of the slab :31

28 m2/m3

25 m2/m3

26 m2/m3

Advantages and flexibility of the ZGS compared to the traditional steel shot system:

- Width of cut generated by the diamond segment: 5 mm instead of 9 mm of the traditional system

- More productivity of the ZGS compared to the traditional gang saw: 38 slabs per meter (+5 slabs compared to the traditional gang saw which is equivalent to +15% of production at every cut)

- More productivity (+15% in terms of square meters produced) a less production of mud - 44% which means: environment protection and money saving for the company.

- Using the water instead of the mixture steel-lime, cancel the need to clean the slabs before completing their processing and this means money saving (about 0.2 €/square meter) and a better work environment.

- Cutting with water also reduce drastically the risks for the operator when they need to go inside the machine to secure the slabs under cutting. The mud, traditionally present in the traditional technology with steel shot system of cut, represents a high risk for the workers for their ordinary job.

- Cutting time for a block with a height of 1.9 meter can be from 17 to 21 hours. This increases the productivity up to 3 times compared to the traditional steel shot system

- ZGS can cut marble / hard marble and stone in general (also marble and granite together).

- ZGS can cut also fragile material.

- Low consumption of energy (1/3 compared to the traditional gang saw being ZGS 3 times faster than a traditional gang saw, -50% compared to the multiwire machine (gang saw cutting width of 3500 with main motor 55 kW)

- More productivity (+15% in terms of square meters produced) a less production of mud - 44% which means: environment protection and money saving for the company.

- Using the water instead of the mixture steel-lime, cancel the need to clean the slabs before completing their processing and this means money saving and a better work environment.

- Cutting with water also reduce drastically the risks for the operator when they need to go inside the machine to secure the slabs under cutting. The mud, traditionally present in the traditional technology with steel shot system of cut, represents a high risk for the workers for their ordinary job.

- Cutting time for a block with a height of 1.9 meter can be from 17 to 21 hours. This increases the productivity up to 3 times compared to the traditional steel shot system

- ZGS can cut marble / hard marble and stone in general (also marble and granite together).

- ZGS can cut also fragile material which both the traditional gang saw and multi wire machine cannot cut.

- Low consumption of energy (1/3 compared to the traditional gang saw being ZGS 3 times faster than a traditional gang saw, -50% compared to the multiwire machine a traditional gang saw, -50% compared to the multiwire machine

The market increasingly requires exotic materials. These materials internally have strong inhomogeneities in the hardness. Everybody know that the alternation of hard zones with soft parts undermines the diamond wire which cannot guarantee acceptable cutting quality. The ZENESIS GANG SAW System, on the other hand, solves this problem by guaranteeing an irreproachable cut quality and excellent precision of the thickness of the final slabs.

How to introduce the Z.G.S system in your machine

The Zenesis gangsaw System (ZGS) is a revolutionary technology of cut for Granite and stone which uses special diamond segments, and water to cut granite blocks into slabs.The diamond blades, in order to cut, need impact against the granite and that is why the ZGS applies to the existing traditional gang saw machines, designed for cutting granite with the steel shot system and the mixture of steel grit and lime.

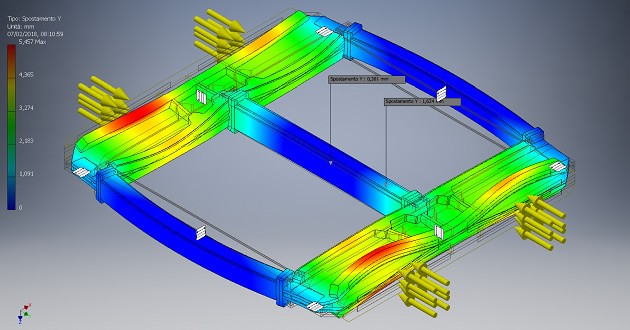

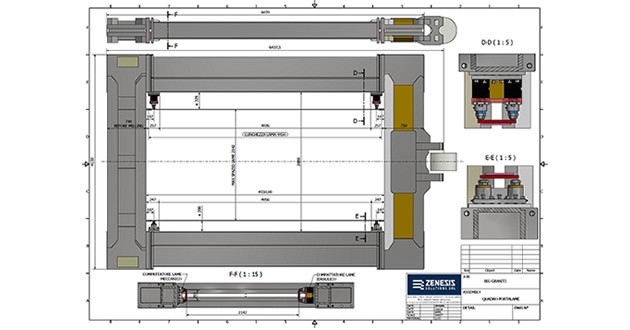

To apply our technology, it is necessary to introduce on the existing machine both new components (new tensioner and special high resistance tie rods) and also a modification of the existing frame which holds the blades, because the Zenesis diamond blades need high tension compared to the old and obsolete steel shot technology.

All the calculation and the project related to the modification of your machine is managed entirely by the Staff of Zenesis Solutions Srl. Here below some example of modified frames.